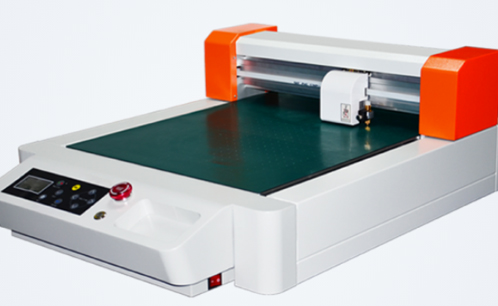

You may be wondering how to determine if you should really consider buying a flatbed plotter. These machines are an effective solution to the five basic needs of graphic, packaging, and printing companies.

If you recognize that you have these types of needs, you should probably carefully consider purchasing a flatbed plotter.

1) Rapid Prototyping

This is essential to help you get projects approved by your clients, as you will be able to quickly see what the finished project will look like and can show the final version to the client immediately.

2) Outsource less work

By outsourcing less, you will be able to speed up the production process and better control quality and costs. From an organizational perspective, in-house production is less risky and you can better manage time and workflow with everything under control.

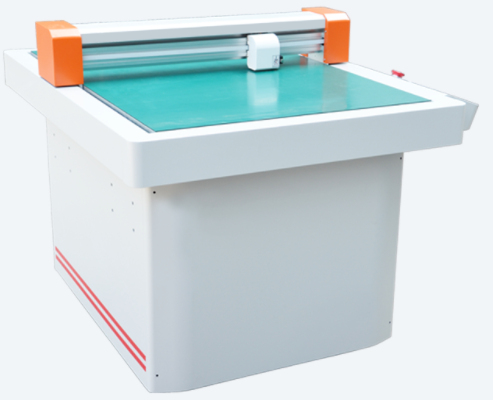

Vinyl Plotter

3) Eliminate start-up cost issues

With a flatbed plotter, you will be able to produce the quantities and minimum production runs required by your customers without restrictions. You will no longer be forced to produce large quantities to reduce start-up costs.

4) Create original projects independently

Without a plotter, you would normally have to rely on external suppliers and adapt pre-made cutting dies: essentially, you would find yourself performing work that others have already done. With a flatbed plotter, on the other hand, you will always be able to design and produce original projects on your own.

5) Just in time - better response to customer deadlines

With a flatbed plotter, you will be able to respond better to the timescales required by your clients. With this type of machine you make it possible for yourself to pre-deliver in a much shorter time, without having to manufacture entire batches in one production process.

Vinyl Plotter

Flatbed plotters vs conventional die-cutting machines

What we have just listed are the main advantages guaranteed by flatbed plotters. Compared to conventional die-cutting machines, this type of machinery is less suitable for cutting large quantities of material. The reason for this is that conventional die-cutting machines are able to complete these processes much faster.

However, comparing the flatbed plotter die-cutting process with a conventional die-cutting process is a mistake to be avoided. This is because the processes are completely different, both in terms of method and concept. When choosing a machine, it is necessary to consider the output we want to achieve. It is the quantity that determines the choice.

You may be wondering if there are two solutions to choose from. Well, it may be absolutely right to choose both solutions, as it allows you to respond to two different needs that may arise in your company and integrate them with each other.

Whereas traditional die-cutting guarantees high volume performance, flatbed plotters offer the flexibility to choose when to produce one way and when to produce the other, depending on cost convenience and the number of machine designs and options available to the company.

Are you interested in learning more about flatbed plotters and how they can benefit you? Contact us today to secure an expert consultation!