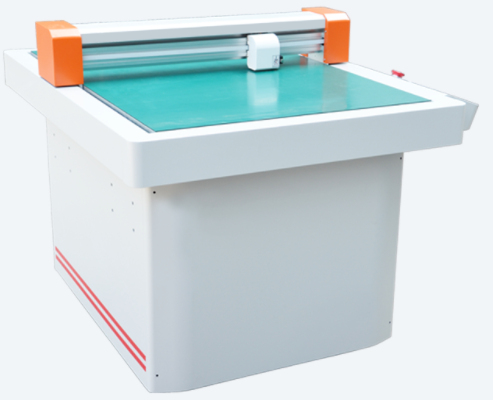

The flatbed digital cutter is a professional cutting tool for flexible materials. It has been widely used in cutting automotive interiors, carpet mats, clothing, packaging materials, textiles, advertising materials, leather, and composite materials. The flatbed digital cutter can choose different blades according to different materials to ensure the best cutting effect.

What is a flatbed digital cutter?

The flatbed digital cutter uses the high-frequency vibration of the blade up and down to cut, front and rear, left and right digital control movement, tens of thousands of vibrations per minute to achieve the cutting effect, fast cutting speed, environmentally friendly processing, suitable for carbon fiber, glass fiber, fiber cotton, prepreg Cloth, aramid, ceramic fiber, cloth, silk loop, leather, felt, carpet, sound-absorbing cotton, silicone, rubber, KT board and other non-metallic flexible materials. The finished product cut by the flatbed digital cutter is also clean and neat, with smooth edges, and the size of the cut pieces is accurate, odorless, relatively environmentally friendly, and soft and hard materials are available. Its cutting speed is twice that of a rotary knife, and the equipment is widely used, such as clothing industry and advertising industry. It is also the first choice of many companies.

What are the advantages of the flatbed digital cutter?

1. Easily solve various problems during die cutting, such as time-consuming and labor-intensive replacement of die die, reducing production efficiency; in addition, feeding system and receiving system can be added according to customer needs, which is more intelligent and labor-saving.

2. The ultra-high frequency vibration knife cutting technology eliminates the irregularity of manual cutting; it is more efficient and faster, making leather and PU cutting an artistic enjoyment.

3. The cutting speed is faster and the efficiency is higher. The frequency of the electric vibrating knife can reach 25000 times/min to provide strong support for high-speed cutting, and the speed can reach 1000mm/s.

4. Effectively solve the disadvantages of laser cutting machine scorching/odor, and more in line with environmental protection requirements; cutting carpets (with PVC at the bottom), the incision is very smooth, and will not produce black edges, burnt and other problems caused by laser cutting. Beautiful, more in line with the needs of end users.

5. Smooth operation, fine and smooth cut, powerful function, can effectively solve various problems such as proofing.

6. The operation interface is simple and practical, easy to learn and easy to use.

What should we pay attention to when using the flatbed digital cutter?

1. The accuracy of the workbench. When the accuracy of the worktable is high, the blades on the worktable will cut with high precision. Of course, the accuracy is also greatly guaranteed. The height of the worktable is high or low, and subtle errors may cause the reduction of cutting accuracy and bring to the factory loss. This has a particularly great impact on the quality of our materials. Where we need to consider, we must look at the whole process of cutting demonstrations to determine whether the accuracy effect is enough!

2. The difference in cutting materials. Depending on the cutting material, it will also affect the choice of cutting blade. Similarly, the precision of cutting cloth and white cardboard is different, which is mainly affected by the thickness and hardness of the material. The thicker the material, the lower the precision and the larger the gap.

3. The sharpness of the blade. The sharpness of the cutting machine blade is also an important factor that affects the cutting accuracy. When the blade is passivated, there is a lot of wear, which affects the cutting of raw materials during the cutting process and affects the cutting accuracy. The material of the blade is good, and the sharpness is very good, but the cutter can switch the blade, and choose different blades according to different materials. Regardless of the blade life, cutting accuracy, cutting speed and cutting quality, a good blade is much higher than a poor quality blade.

We are a flatbed digital cutter supplier. Please feel free to contact us if you need them!